Technology of making Flush Doors.

Flush doors are the unique choice for almost all types of buildings

- residential, commercial, institutional, high-rise and other

construction and architectural buildings. The details given in this

page are designed to help you decide the right choice that meets your

needs and tastes.

Broadly, there are two kinds of flush doors - the hollow core door

with a timber frame covered over with plywood / hardboard and the solid

core door. The latter may have either a large number of timber reapers,

or a single particle board forming the core. We at Madras Chipboard

Ltd., have chosen solid particle board as the core for our LAXMI FLUSH

DOOR in view of its strength, sturdiness and durability.

Technical Details :

CORE

FRAMES

ASSEMBLY

Customers' Choice:

Face Veneers

Lipping

Double Shutter

Single Door with Vision Hole

Plastic Coating

Special Shapes

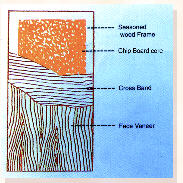

CORE:

Particle boards are manufactured with selected species of soft

and medium hard wood particles: the particles are dried, graded and

mixed with Phenol / Urea Formaldehyde resin and pressed at high

temperature and pressured into boards of required thickness. As the

particles are carefully graded and glued together with thermosetting

resin, there are no voids to harbour insects and fungal. This treatment

makes our flush doors

anti-bore and

anti-termite. Since the particles are random-oriented, the finished

board has almost equal strength in all directions compared to ordinary

timber, whose strength values along and across the grains are vastly

different. The particle board is available in sizes much larger than

what is normally feasible with natural timbers.

FRAMES:

The framework of the shutter is made out of natural timber. The normal

width of a flush door frame is 85mm wide with the thickness specified by

the customer that fits the thickness of the finished flush door.

Suitable species of medium-hardwood sizes are selected and impregnated

with specific chemical preservatives using the latest Full-cell Vacuum

Process ti minimize insect attack. The sizes are then seasoned to stable

moisture levels in the Kiln-Seasoning Process: natural timber may have

from 35 to 150% moisture. Such high moisture contents lead to warping

and cracking of the timber when the surrounding air becomes dry, and

bulging when the humidity increases. Once the timber is seasoned to its

stable moisture level - 8 to 10% depending upon the species - it becomes

immune to the changes in the atmospheric humidity.

ASSEMBLY:

The treated timber frames are assembled together with special fasteners,

the particle board core is laid within and fastened to the frames; the

entire assembly is covered with cross band veneers on both sides

(parallel to the width of the door) followed by face veneers (parallel

to the height) thus making a 5-ply construction (core +2 cross bank +2

face veneers) for unmatched strength and sturdiness. Boiling water proof

Phenol

Formaldehyde thermo-setting resin is used for gluing the veneers to the

door to ensure durability. The door is then hot-pressed in special

hydraulic presses at 130 C - 140 C and 200 - 220 psi. Normal finished

thickness

of doors may be 19,25,30 and 38 mm.

Customers' Choice:

Face Veneers: Depending on the proposed final finish,

the face veneers may be commercial (for painting) or decorative (for

polishing); Doors/Boards can even have one side commercial and the other

side decorative. While

Teak veneers are widely used as decorative face veneers, other veneers

such as Rosewood, Mahogany, Walnut etc., can also be made for special

bulk orders.

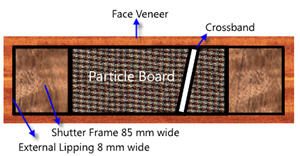

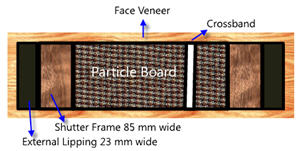

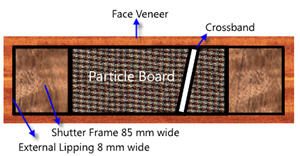

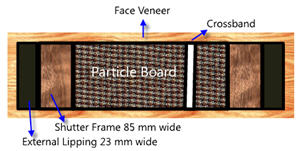

Lipping: Teak or similar hardwood

reapers, fixed to some or all the edges of the flush door are called

'Lipping' their intended function being to enhance screw-holding

capacity and to protect the door against moisture ingress. The lipping

may be external (visible as a beading around the door) or internal

(covered over by the face veneer). The external lipping is usually not

more than 8mm wide and is screwed to the door, while the internal

lipping is about 23mm wide and glued to the door with thermosetting

resins and hot-pressed. Any planing at site at the time of mounting the

door will have to be well within these limits. It may be noted that

chemical-impregnated and kiln-seasoned shutter frames of the flush door

have adequate screw holding capacity and give ample protection against

moisture.

External Lipping an illustration:

Internal Lipping an Illustration:

Double Shutter

Double Shutter: For wide door, the shutter may be made

in two leaves, either equal or unequal; this should be specified clearly

in the Purchase Order, stating the width of the door in the closed

position as well as the

width of each leaf if they are unequal. For such doors, we can provide

rebate-cutting if required; the swing of the door - Right hand inside

opening or Left hand inside opening - must be specified in the Purchase

Order.

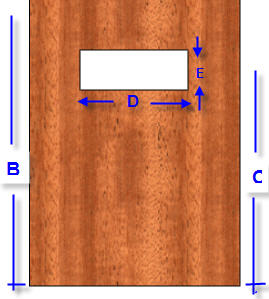

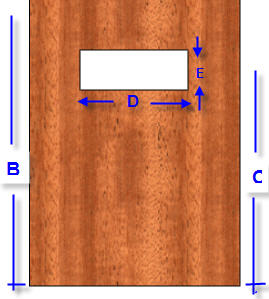

Vison panels and Louvers:

If specified in the Purchase Order, we will provide cut-outs in the

shutter with trimming reapers around for fixing vision panels or

louvers: the size of the cut-out required along with the height above

the bottom of the door to the bottom of the panel/louver should be

clearly stated, preferably with a rough sketch.

Plastic coating

Plastic coating: The finished door may be given a coat

of Phenol Formaldehyde all over: the trade believes that such a coating

improves the weather-resistance of the door, making it External Grade

suitable for use in

special locations like bathrooms.

Special Shapes: Being an engineered product, the flush

door need not always be rectangular: it can be made into any shape as

per the wishes of the client. However, the arch shape with a curved top

style is very much in

vogue. Here again, the exact should be specified.

Flush doors have become an inseparable part of our daily life. Now that

you have a fair idea of the way the flush doors are made and the various

possibilities available, we hope you would be better-equipped to make

the

right choice.

We, at MADRAS CHIPBOARD LTD., have over three decades of experience in

manufacturing high quality LAXMI FLUSH DOOR. We keep ourselves always abreast (if not ahead) of the

rapid developments taking place in this field, so that we may continue

to provide our valued clientele with State-of-Art products that are good

value for money.

See

Gallery to view the designs of Laxmi

Flush Doors.

To know more and to place your orders, please

Contact us.